Turbo Sifter is used to sieve dry raw material in powder form before it is fed to Rapid mixer &wet granulator or High shear mixer. The Turbo sifter is suitable for separation of foreign objects from dry powder before mixing. One can use mesh size from 4 to 25. This machine is used for mainly screening the formulations (in form of dry powder) before feeding it in to the high shear mixer or Fluid bed granulator.

Dry powder is fed to Turbo Sifter through IPC or intermediate product container by positioning the IPC over the infeed mouth of the sifter. Normally IPC's are raised over the mouth of Turbo Sifter by using a lifting and positioning device or hoist. Lower portion of IPC is lowered inside the Turbo Sifter inlet through a special gasket which ensures totally dust free transfer. Now this powder after entering the turbo sifter is pushed towards the sieve area by screw in the sieve chamber. There are blades which while rotating push the material against the sieve. Sieved material will fall through the bottom opening.

By using silicon rubber sleeve, this sieved material is transferred to RMG through a gasket of special design which ensures complete dust free system.

As an option frequency drive (AC drive) system can be provided whereby one can vary rpm as desired by the process. Entire Turbo sifter can be mounted on a swiveling pillar over the frame of Rapid Mixer, which can raise or lower the Turbo Sifter and also it can rotate the assembly completely by 360°.

Turbo sifter can also be mounted on castor wheel for mobility. Entire assembly and sieves can be removed for cleaning very easily.

Capacity: 400 kg/hour depending upon the physical properties of the product.

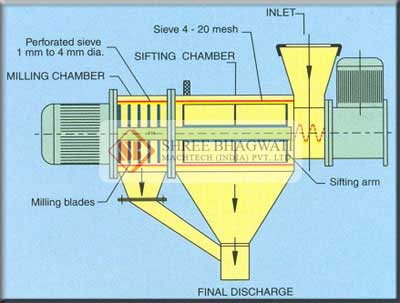

The Turbo mill is suitable for sifting and milling of dry granules. One can use mesh size from 4 to 25 as per user's requirement for sifting and perforated sieve of 1mm dia to 2.5mm diameter holes.

Powder is fed to Turbo mill through infeed hopper of the Turbo mill. Now this powder after entering the Turbo mill is pushed forward by screw in the sieve chamber. There are blades which while rotating push the material against the sieve.

Sieved material will fall through the 250 diameter opening. Over size material than passes through set of milling blades that cuts the oversize granules and make it as per the perforation size required. Using silicon rubber sleeve, this sieved material is transferred to Container of suitable size through a gasket of special design which ensures complete dust free system . Sieved chamber granules along with sifted granules come together in a common pipe of 250 diameter. Entire assembly and sieves can be removed for cleaning very easily.

As an option frequency drive (ac drive) system can be provided whereby one can vary rpm depending upon the requirement. This facility is offered as an optional on request. Entire is mounted over the pipe structure of 75mm dia pipes of S.S. 304 with castor wheels at the bottom. There are two fixed castors and two swiveling castors made of UHMW , with S.S. 304 side bracket and ball bearings for extra heavy duty application. Turbomill is widely used to mill dry granules with minimum of dust generation in the production area.

Capacity : 300-400 kg/hour depending upon the physical properties of the product.

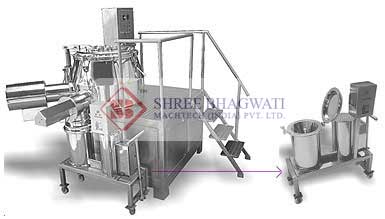

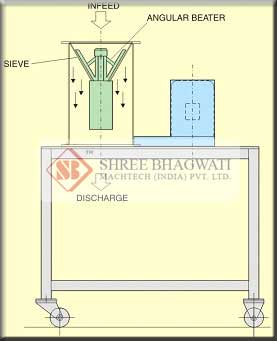

Cone mill is used for milling wet and dry granules using a conical sieve. It is used to downsize wet/dry granules using a angular beater and a conical sieve. It is mounted on a S.S. pipe tubular stand with four castor wheels at the bottom. The cone mill can be moved from one place to another very easily. As seen in the drawing there is a conical sieve of the required mesh size and an angular beater which is rotating within close clearance with the sieve. This angular beater can be removed for cleaning along with the sieve from the top very easily. Angular beater can be raised or lowered using a knob so the distance between the beater and sieve can be varied depending upon the requirement.

It can be directly mounted on a pivot below the discharge of the high shear mixer granulator and here depending upon the product which needs wet milling the Cone mill can be used. It can be used for dry milling of granules by mounting it over a trolley and loading material through an IPC or intermediate product container. Using special type of Silicon rubber gasket one can ensure dust free operation. Machine also has a dust filter which does not allow powder to escape out when the dry powder is being milled.

Capacity: 300 Kg per hour, depending upon the physical property of the product.

Cone mill mounted over separate trolley and receiving wet granules from Rapid Mixer and Wet Granulator for downsizing.